Order PCB

The easiest and fastest way to order the PCB is LibrePCB Fab. It automatically exports and uploads all the necessary production data files without annoying you with the whole traditional production data workflow. See fab.librepcb.org/about for more information.

|

You prefer to manually generate the production data files? Or you want to use a PCB manufacturer not available at LibrePCB Fab? No problem! Just skip this section and go to Generate Production Data. |

LibrePCB Fab

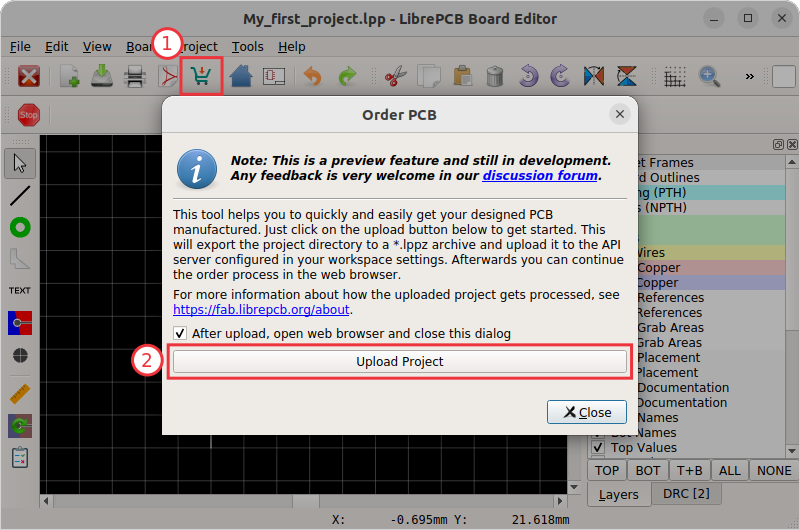

To start the order process, click the Order PCB toolbutton in either the schematic- or board editor:

With Upload Project, the project is uploaded to our order service fab.librepcb.org. Then your web browser should open a website where you can review and continue the order.

|

Alternatively you could also export your LibrePCB project as a |

Generate Production Data

Instead of using LibrePCB Fab, of course you can also generate the production data manually and forward these files to any PCB manufacturer you like.

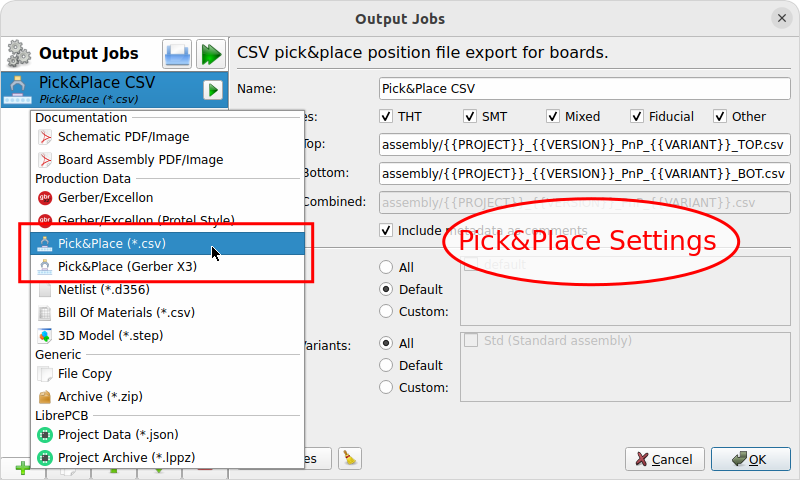

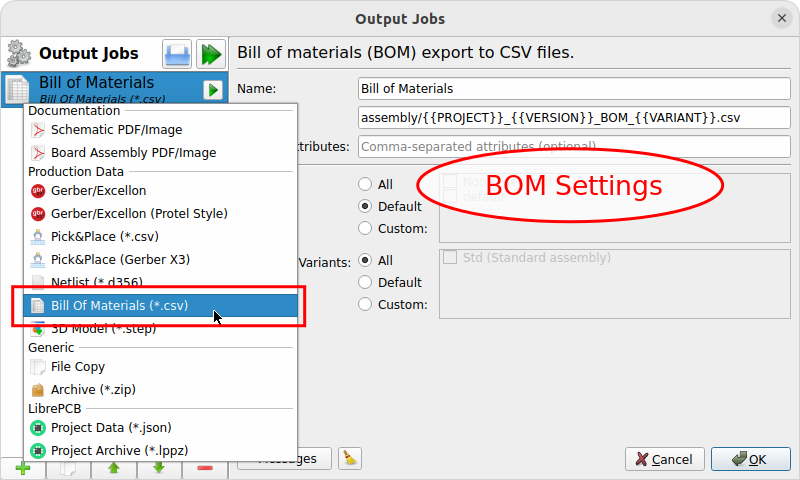

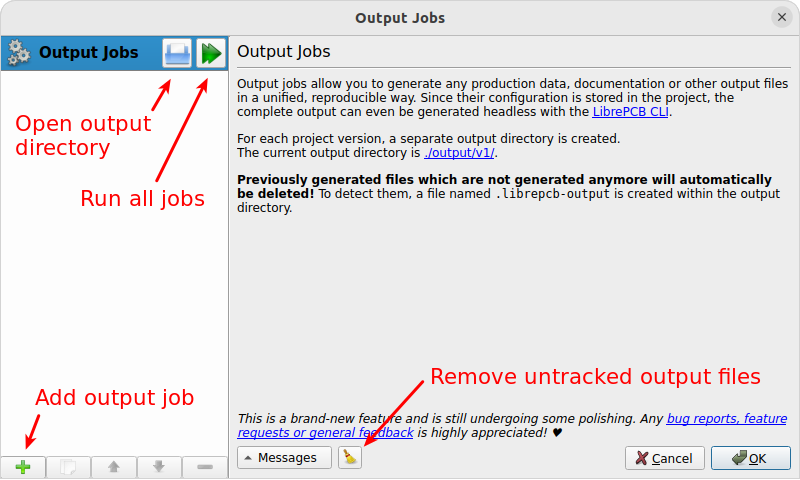

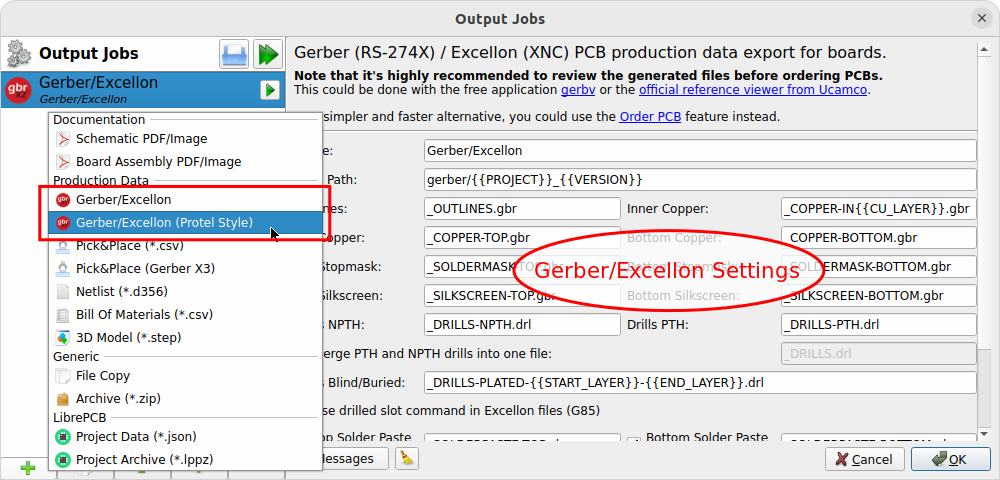

Currently there exist multiple ways how to generate production data, but it’s recommended to use the Output Jobs feature for that. Click on or press F11 to open the corresponding window:

Then for any output you like to generate, click on the + button at the bottom left. See the following sections for details on the available jobs.

|

Any files generated through output jobs will be written to the path

|

Once you set up all output jobs, just click on the "Run all jobs" button and all files will be written to the output directory. Then click on OK and save the project to store the output jobs configuration.

Gerber/Excellon

For the Gerber/Excellon production data you need to choose the settings of the Gerber/Excellon export. There are two different presets built-in, a default style and a Protel style. Generally you should determine what format your PCB manufacturer accepts. Many manufacturers accept Protel-style settings, so if you’re unsure, choose Gerber/Excellon (Protel Style).

If required, the settings can now be adjusted manually.

|

It’s highly recommended to cross-check the generated files with third-party tools like gerbv or the reference Gerber viewer. LibrePCB developers are not responsible for any implications caused by wrong production data. |